mod note : clarification on issue and resolution.

(by @thetechnobear)

for some users of the original (pre June 2022) , the knob cap on the encoders is pushing down a bit too far on its shaft. this means the the switch does not activate every time correctly you press it.

this may occur after a short time of using, as the knob ‘wears in’.

simple workaround

remove the knob cap, and place a small amount of paper into the cap.

(you can put a bit, then add more if necessary)

this will mean the the cap will no longer push down so far, and so the encoder can go thru its expected travel, and so get proper switch activation every time. as the paper won’t compress anymore, this will solve the problem for good.

however, if you wish to have knobs replaced with a revised design this is now possible…

replacement program

Squarp are offering a free replacement of knobs to anyone affected by this issue. details in this post about how to get these revised knobs.

custom knobs

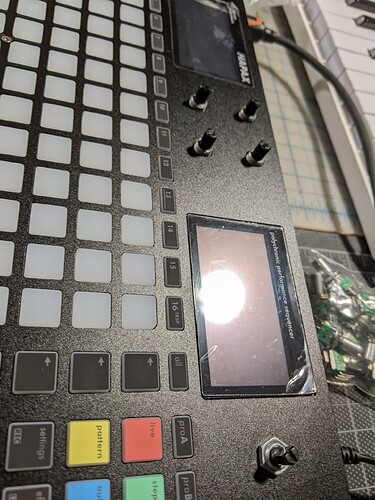

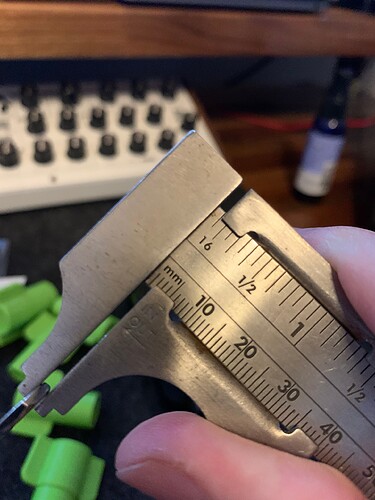

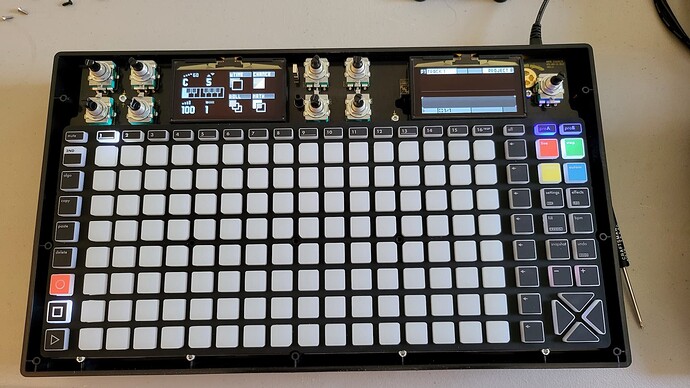

another option some users have opted for is to replace with other knobs… e.g. with different colours, or feel… personalise your hapax ![]() they are pretty common 6mm D shaft knobs, just be careful with ‘depth’ and also spacing between them - examples have been posted in this topic.

they are pretty common 6mm D shaft knobs, just be careful with ‘depth’ and also spacing between them - examples have been posted in this topic.

(I quite fancy some nice aluminium ones … need to do some shopping !)

important note: this only effects the first product run units, from June 2022 new units will have the new revised knobs.

of course, if you have any questions related to this, please contact Squarp via the contact form

EDITED: to make reference to the revised knobs and replacement program for early units.

(apologies to @jps, for hijacking your post.)

Here’s another issue I encountered tonight…

The knobs are not a perfect match for the encoders. If the knob is fully seated, the encoder’s switch can not be activated. This means that any UI feature that requires a press of the button will no longer work.

If I ease out the knob just a touch, the button starts to work again, only until the knob fully seats again.

I think I fixed this by inserting a small ball of electrical tape into the knob. If this fix persists, I might try a dab of glue in the knob instead.